Home >> PRODUCTS >> Titanium Equipment

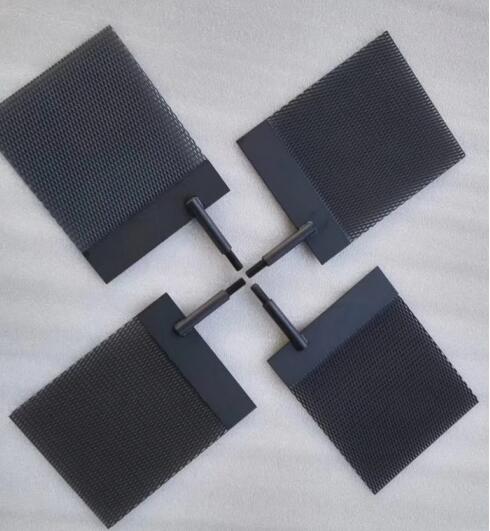

Material: TA1, TA7, TA9, TA10, TA15, TA18, TA19, TC4, TC6, TC11, TC18, TB6 Execution standard: GB/T16598-1996, GB/T13810-2007, GB/T2965-2007 1. Brand number, specification and status Brand: TA1,TA7,TA9,TA10, TA15, TA18, TA19, TC4,TC6, TC11, TC18, TB6 Specification: ¢50--1200mms; L 30----600mm Delivery status: Annealed (M) hot working (R) cold working (Y) (annealed, supergenerating wave detection). Processing technology: melting - flaw detection - forging - annealing - car light - flaw detection. Metallographic structure: crystal structure level is available from A3 to A4. Standard: GB/T16598-1996, GB/T13810-2007, GB/T2965-2007, ASTM B381, ASTM B348, ASTM F67,ISO5832-2ASTM F136, ISO5832-3, AMS4928, MIL4911. Application: medical, aviation, military industry, petrochemical, metallurgy, electroplating, vacuum coating, sports and other industries Note: other specifications or types of products can be supplied through consultation between both parties. 2. Products with permissible size deviation (mm). Origin: Baoji City, Tiangu, China Supplier: Shaanxi Kaber Non-ferrous Metal Co., LTD Delivery: single weight more than 50 kg logistics: Deppon, Aneng, Kanglong, Huayu, Jiaji and so on. Rail express is also available. Small express delivery: Zto, Huitong, YTO, Yunda, SF express, etc. Packing: wooden case, woven bag, pearl cotton, bubble pad, carton, etc |